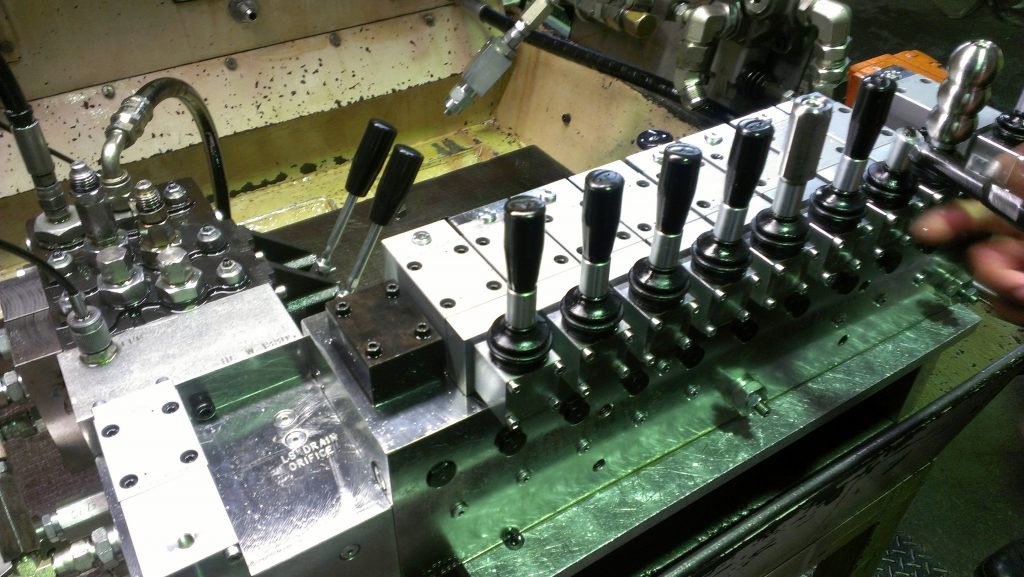

Mining Machine Control Levers

The Problem:

It is a very robust environment for the operating equipment in an underground mine. Large mining machines are driven by hydraulics and there are many levers that the miners use to operate the equipment. One of the issues that caused inconvenient disruption and down time for repairs and maintenance was damaged control levers. Apart from the cost of the disruption and of the maintenance itself, there was a safety issue of possible oil leaks and spillages during the replacement of parts, leading to a hazardous situation in the dimly lit and dusty environment of the mine.

The Solution

The customer required stronger control levers that had a more robust design than the standard commercially available levers and came to us to solve this problem.

They clearly required a customised solution but design changes were challenging due to the already tight existing constraints. Following extensive research of materials, treatments, coatings, and other features a combination of special parts, linkages, features, and design led to a prototype for testing in the field.

The new design has reduced unplanned stoppages and maintenance costs and has eliminated the oil leakage and spillages leading to a safer working environment for the miners.