Piloted Operated Water Valve

The Problem:

A pilot operated water valve used to feed water to a dust suppression spray system that was designed by a customer for their underground longwall mining machines, could not cope with the harsh underground mining environment. It was found to be unreliable, sticking and beset with intermittent pilot failures that they were unable to resolve. This issue created a safety hazard for the people working in the mines and led to considerable downtime and maintenance costs.

The Solution

The customer came to us to develop a new pilot operated water valve that would work efficiently in the above application. The process commenced with a thorough review of all the issues and confirmation of the actual parameters that would determine the operational requirements and specification for the valve.

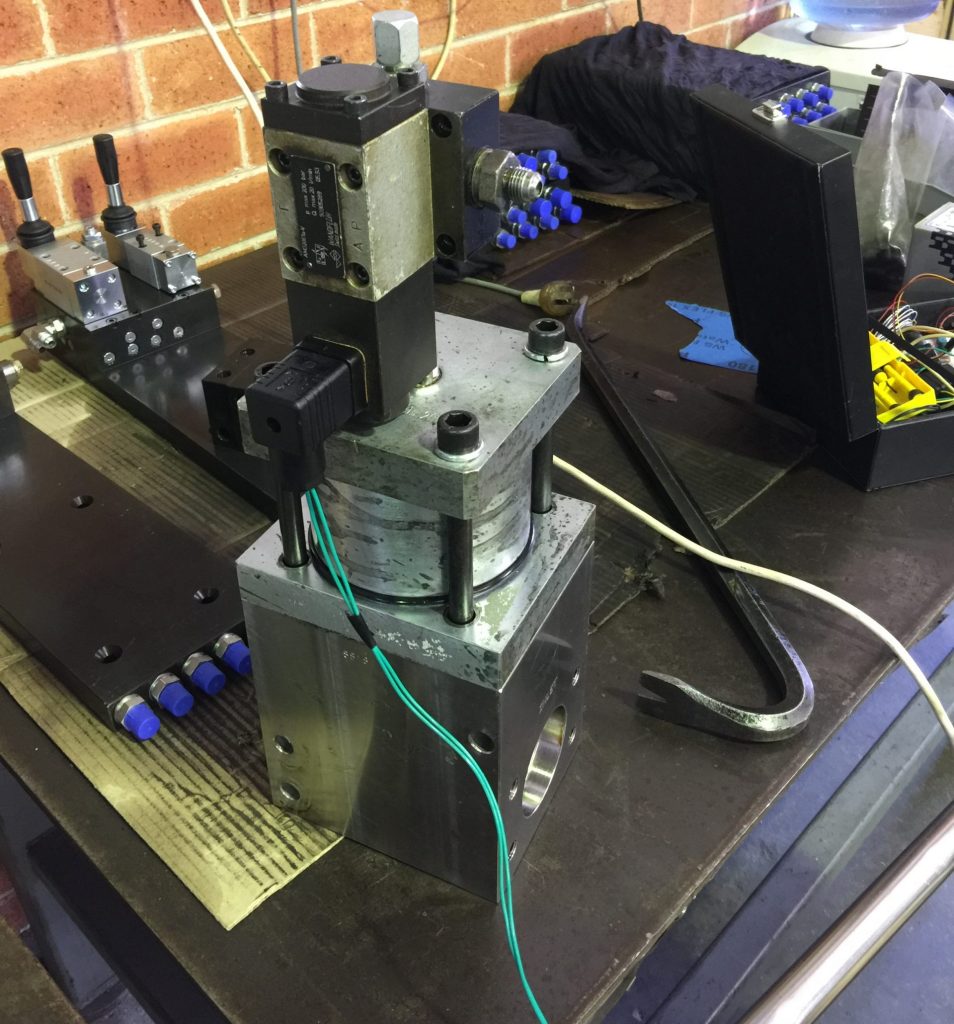

A more robust design was developed, both internal and external with reinforced components, special bushings and guiding systems and at the same time reducing the operating pressure to operate the valve by more than two thirds, whilst providing for an impure water flow of 900 litres per minute. A prototype was developed and tested on site and on approval has been rolled out the customer’s fleet of longwall machines.

The new units have virtually eliminated the unplanned stoppages and maintenance requirements greatly reducing maintenance and stoppage costs. Further, it has greatly lowered the potential health risks to the people working in the mines making it much safer workplace for everyone.